Sake dawo da kayan aiki mataki ne mai mahimmanci a cikin tsarin SMT.Bayanin yanayin zafin jiki mai alaƙa da sake kwarara shine muhimmin ma'auni don sarrafawa don tabbatar da haɗin haɗin sassa.Ma'auni na wasu abubuwan haɗin kai kuma za su shafi bayanin martabar zafin jiki kai tsaye da aka zaɓa don wannan matakin na aiwatarwa.

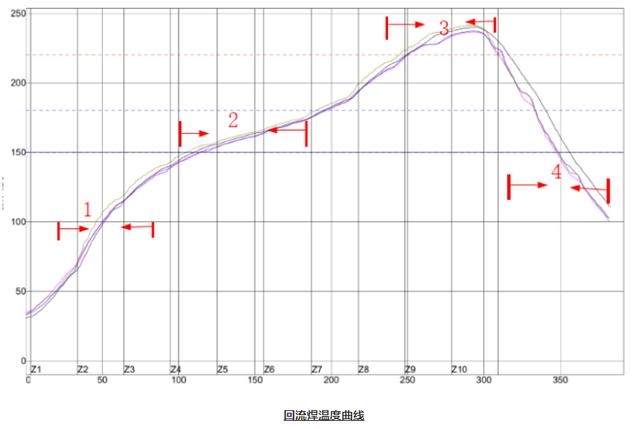

A kan na'ura mai ɗaukar waƙa biyu, alluna tare da sabbin abubuwan da aka sanya suna wucewa ta wurare masu zafi da sanyi na tanda.An tsara waɗannan matakan don sarrafa daidaitaccen narkewa da sanyaya na mai siyar don cika haɗin ginin.Babban canje-canjen yanayin zafi da ke da alaƙa da bayanin martaba na sake kwarara za a iya raba shi zuwa matakai/yankuna huɗu (wanda aka jera a ƙasa kuma aka kwatanta nan gaba):

1. Dumi

2. Dumama akai-akai

3. Yawan zafin jiki

4. Sanyi

1. Yankin preheating

Manufar yankin preheat shine don daidaita ƙananan abubuwan da ke narkewa a cikin manna mai siyarwa.Babban ɓangarorin juzu'i a cikin manna solder sun haɗa da resins, masu kunnawa, masu gyara danko da kaushi.Matsayin da sauran ƙarfi shine galibi azaman mai ɗaukar guduro, tare da ƙarin aikin tabbatar da isassun ma'ajiyar manna solder.Yankin preheating yana buƙatar canzawa mai ƙarfi, amma yanayin hawan zafi dole ne a sarrafa shi.Matsakaicin adadin dumama na iya dagula yanayin yanayin zafi, wanda zai iya lalata sashin ko rage aikinsa/rayuwar sa.Wani illar da ke tattare da yawan dumama shi ne cewa manna mai siyar zai iya rugujewa kuma ya haifar da gajeriyar kewayawa.Wannan gaskiya ne musamman ga manna masu siyarwa tare da babban abun ciki.

2. Yankin zafin jiki na dindindin

Saitin yankin zazzabi akai-akai ana sarrafa shi a cikin sigogin mai siyar da manna mai siyarwa da ƙarfin zafi na PCB.Wannan mataki yana da ayyuka guda biyu.Na farko shine don cimma daidaiton zafin jiki ga dukkan allon PCB.Wannan yana taimakawa rage tasirin damuwa na thermal a cikin yankin sake kwarara kuma yana iyakance sauran lahani na siyarwa kamar ɗaga abubuwan ƙara girma.Wani muhimmin tasiri na wannan mataki shi ne cewa juzu'i a cikin manna solder fara mayar da martani ga m, ƙara wettability (da surface makamashi) na weldment surface.Wannan yana tabbatar da cewa narkakkar solder ɗin ya jika saman saida da kyau.Saboda mahimmancin wannan ɓangaren aikin, lokacin jiƙa da zafin jiki dole ne a kula da su da kyau don tabbatar da cewa juzu'in ya wanke saman saidarar gabaɗaya kuma ba a gama cinyewa gaba ɗaya ba kafin ya kai ga aikin sake fitarwa.Wajibi ne a riƙe juzu'i yayin lokacin sake gudana yayin da yake sauƙaƙe tsarin jikawar solder kuma yana hana sake yin iskar oxygen da farfajiyar da aka siyar.

3. Yankin zafin jiki:

Yankin zafin jiki mai girma shine inda cikakken narkewa da jikawar amsa ke faruwa inda Layer intermetallic ya fara samuwa.Bayan kai matsakaicin zafin jiki (sama da 217 ° C), zafin jiki ya fara raguwa kuma ya faɗi ƙasa da layin dawowa, bayan haka mai siyar ya ƙarfafa.Wannan bangare na tsarin kuma yana buƙatar kulawa da hankali don kada zafin jiki na sama da ƙasa ya sa sashin ya girgiza.Matsakaicin zafin jiki a cikin yankin sake kwarara ana ƙaddara ta yanayin juriya na abubuwan da ke da zafin zafi akan PCB.Lokaci a cikin babban yankin zafin jiki ya kamata ya zama ɗan gajeren lokaci don tabbatar da cewa abubuwan da aka gyara suna walƙiya da kyau, amma ba da daɗewa ba Layer na intermetallic ya zama mai kauri.Mafi kyawun lokacin a wannan yanki shine yawanci 30-60 seconds.

4. Yanki mai sanyaya:

A matsayin wani ɓangare na gabaɗayan tsarin siyar da sake kwarara, ana yin watsi da mahimmancin wuraren sanyaya.Kyakkyawan tsarin sanyaya kuma yana taka muhimmiyar rawa a ƙarshen sakamakon walda.Kyakkyawan haɗin gwiwa ya kamata ya zama mai haske da lebur.Idan tasirin sanyaya ba shi da kyau, matsaloli da yawa za su faru, kamar haɓakar abubuwan haɓaka, mahaɗar solder mai duhu, filayen haɗin gwiwa marasa daidaituwa da kauri na tsaka-tsakin fili na tsaka-tsaki.Saboda haka, reflow soldering dole ne ya samar da kyakkyawan bayanin martaba, ba da sauri ba kuma ba a hankali ba.Yayi sannu a hankali kuma kuna samun wasu abubuwan da aka ambata marasa kyau na sanyaya.Yin sanyi da sauri na iya haifar da girgizar zafi zuwa abubuwan da aka gyara.

Gabaɗaya, mahimmancin matakin sake kwararar SMT ba za a iya yin la'akari da shi ba.Dole ne a gudanar da tsari da kyau don sakamako mai kyau.

Lokacin aikawa: Mayu-30-2023