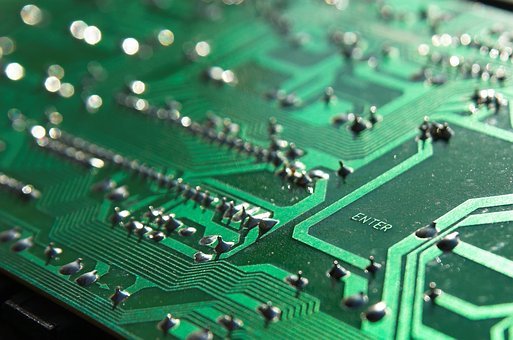

PCB (Printed Circuit Board) yana taka muhimmiyar rawa a rayuwar yau.Ita ce tushe da babbar hanya ta kayan aikin lantarki.A wannan batun, ingancin PCB yana da mahimmanci.

Don bincika ingancin PCB, dole ne a yi gwaje-gwajen dogaro da yawa.Sakin layi na gaba shine gabatarwar gwaje-gwaje.

1. Gwajin gurbataccen Ionic

Manufa: Don duba adadin ions da ke saman allon da'ira don tantance ko tsaftar hukumar ta cancanta.

Hanyar: Yi amfani da 75% propanol don tsaftace samfurin samfurin.Ions na iya narke cikin propanol, canza halayensa.Ana yin rikodin canje-canje a cikin haɓakawa don ƙayyade taro na ion.

Daidaitaccen: ƙasa da ko daidai da 6.45ug.NaCl/sq.in

2. Chemical juriya gwajin na solder mask

Manufa: Don bincika juriya na sinadarai na abin rufe fuska

Hanyar: Ƙara qs (ƙididdigar ƙididdigewa) dichloromethane dropwise a saman samfurin.

Bayan ɗan lokaci, shafa dichloromethane tare da farin auduga.

Bincika don ganin idan audugar ta lalace kuma idan abin rufe fuska ya narkar da shi.

Standard: Babu rini ko narke.

3. Taurin gwajin solder mask

Manufa: Duba taurin abin rufe fuska

Hanyar: Sanya allon a kan shimfidar wuri.

Yi amfani da daidaitaccen alkalami na gwaji don zazzage kewayon taurin kan jirgin har sai babu tabo.

Yi rikodin mafi ƙarancin taurin fensir.

Standard: Matsakaicin taurin yakamata ya zama sama da 6H.

4. Gwajin ƙarfin cirewa

Manufa: Don duba ƙarfin da zai iya tube wayoyi na tagulla akan allon kewayawa

Kayan aiki: Gwajin Ƙarfin Kwasfa

Hanyar: Cire wayar jan ƙarfe aƙalla 10mm daga gefe ɗaya na ma'auni.

Sanya farantin samfurin akan mai gwadawa.

Yi amfani da ƙarfi tsaye don cire ragowar waya ta jan ƙarfe.

Ƙarfin rikodin.

Ma'auni: Ƙarfin ya kamata ya wuce 1.1N/mm.

5. Gwajin solderability

Manufa: Don duba solderability na pads da ta-ramuka a kan allo.

Kayan aiki: na'ura mai siyarwa, tanda da mai ƙidayar lokaci.

Hanyar: Gasa jirgin a cikin tanda a 105 ° C na 1 hour.

Tsoma ruwa.Sanya allon da ƙarfi a cikin injin solder a 235 ° C, sannan a fitar da shi bayan daƙiƙa 3, duba wurin kushin da aka tsoma a cikin kwano.Sanya allo a tsaye a cikin injin siyarwa a 235 ° C, fitar da shi bayan dakika 3, sannan a duba ko an tsoma ramin a cikin kwano.

Ma'auni: Yawan yanki ya kamata ya fi 95. Duk ta ramuka yakamata a tsoma su cikin kwano.

6. Gwajin hawan jini

Manufa: Don gwada ƙarfin jurewar wutar lantarki na allon kewayawa.

Kayan aiki: Gwajin Hipot

Hanyar: Tsaftace da bushe samfurori.

Haɗa allon zuwa mai gwadawa.

Ƙara ƙarfin lantarki zuwa 500V DC (kai tsaye a halin yanzu) a ƙimar da bai fi 100V/s ba.

Riƙe shi a 500V DC don 30 seconds.

Daidaito: Kada a sami kuskure akan kewaye.

7. Gwajin canjin yanayin gilashi

Manufar: Don duba yanayin canjin gilashin farantin.

Kayan aiki: DSC (Bambancin Scanning Calorimeter) mai gwadawa, tanda, bushewa, ma'aunin lantarki.

Hanyar: Shirya samfurin, nauyinsa ya zama 15-25mg.

An gasa samfuran a cikin tanda a 105 ° C na tsawon sa'o'i 2, sa'an nan kuma sanyaya zuwa dakin da zafin jiki a cikin injin daskarewa.

Sanya samfurin akan matakin samfurin na gwajin DSC, kuma saita ƙimar dumama zuwa 20 ° C/min.

Duba sau biyu kuma yi rikodin Tg.

Standard: Tg ya kamata ya zama sama da 150 ° C.

8. CTE (coefficient of thermal expansion) gwajin

Manufar: CTE na hukumar tantancewa.

Kayan aiki: TMA (thermomechanical analysis) mai gwadawa, tanda, bushewa.

Hanyar: Shirya samfurin tare da girman 6.35 * 6.35mm.

An gasa samfuran a cikin tanda a 105 ° C na tsawon sa'o'i 2, sa'an nan kuma sanyaya zuwa dakin da zafin jiki a cikin injin daskarewa.

Sanya samfurin a kan matakin samfurin na gwajin TMA, saita ƙimar dumama zuwa 10 ° C / min, kuma saita zafin ƙarshe zuwa 250 ° C.

Yi rikodin CTEs.

9. Gwajin juriya na zafi

Manufar: Don kimanta juriya na zafi na jirgi.

Kayan aiki: TMA (thermomechanical analysis) mai gwadawa, tanda, bushewa.

Hanyar: Shirya samfurin tare da girman 6.35 * 6.35mm.

An gasa samfuran a cikin tanda a 105 ° C na tsawon sa'o'i 2, sa'an nan kuma sanyaya zuwa dakin da zafin jiki a cikin injin daskarewa.

Sanya samfurin akan matakin samfurin na gwajin TMA, kuma saita ƙimar dumama a 10 ° C / min.

An ɗaga zafin samfurin zuwa 260 ° C.

Chengyuan Masana'antu ƙwararrun Mai kera Injin Rufaffen

Lokacin aikawa: Maris 27-2023